Understanding Hydrogen Cyanide and Its Risks

Hydrogen cyanide is a highly toxic compound that poses significant health risks around various industrial applications. As industries increasingly prioritize safety measures, understanding hydrogen cyanide and its implications becomes crucial, which is where a Hydrogen Cyanide detector plays an essential role.

What is Hydrogen Cyanide?

Hydrogen cyanide (HCN) is a colorless, poisonous gas with a faint bitter almond odor, recognized as a potent chemical weapon and a dangerous byproduct of various industrial processes. HCN is commonly produced during the combustion of nitrogen-containing materials and is utilized in several sectors, particularly in chemical manufacturing, metal processing, and mining. Despite its utility in industry, the risks associated with HCN demand rigorous safety protocols and effective detection systems.

Health Impacts of Exposure

Exposure to hydrogen cyanide can have severe health implications, which can arise from inhalation, ingestion, or skin absorption. Acute exposure can lead to symptoms like headache, dizziness, and nausea. At higher concentrations, HCN can cause respiratory failure, unconsciousness, or even death in minutes. Understanding these health impacts reinforces the necessity for industries using or working near hydrogen cyanide to implement reliable detection measures.

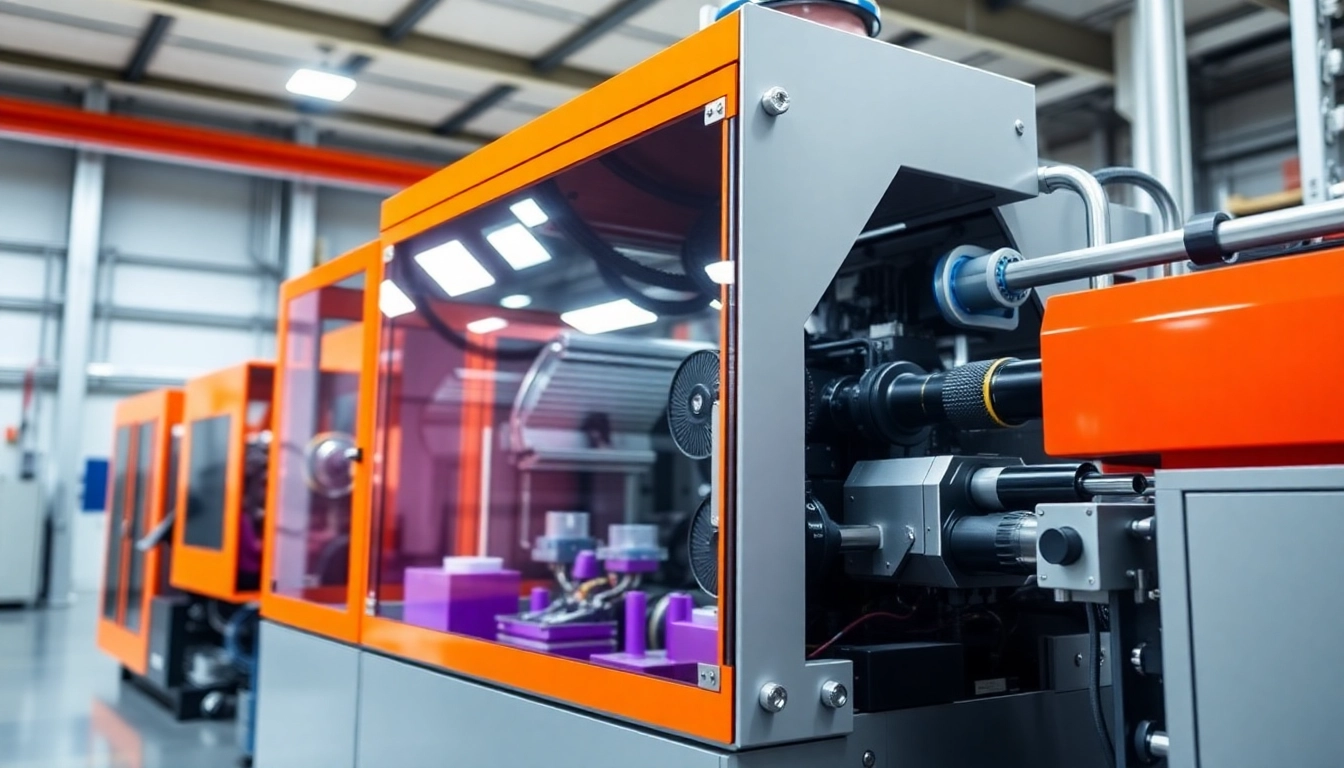

Industrial Applications and Hazards

Industries such as mining, metallurgy, and plastic manufacturing often handle hydrogen cyanide. In these settings, the compound is used to extract valuable metals or synthesize materials. However, along with its practical uses, HCN represents significant hazards, including accidental releases and exposure incidents, stressing the pressing need for systems to detect and monitor HCN levels effectively.

Types of Hydrogen Cyanide Detectors

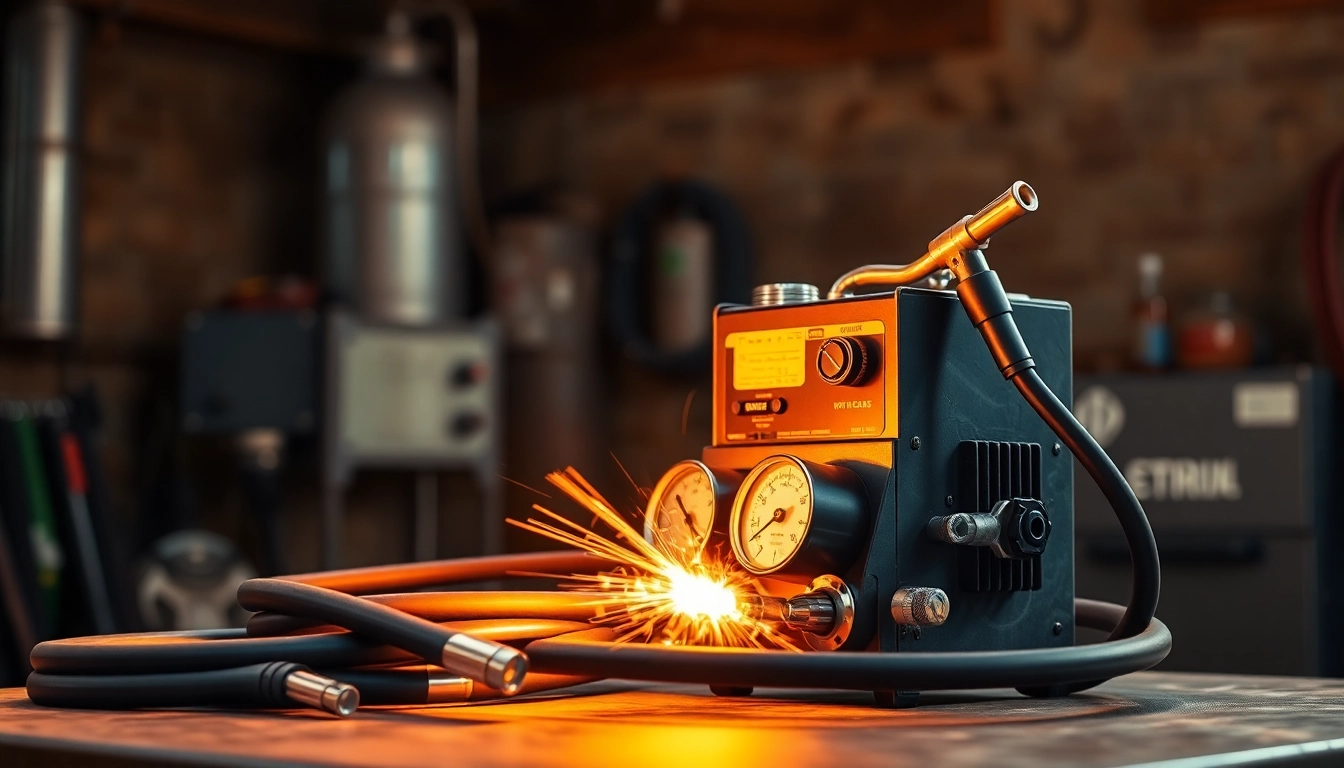

Portable vs. Fixed Detectors

Hydrogen cyanide detectors can be broadly classified into portable and fixed detectors, each serving unique purposes. Portable detectors offer flexibility and mobility, allowing personnel to monitor for HCN in various locations and situations. Conversely, fixed detectors provide continuous monitoring at predetermined areas in a facility, providing real-time alerts and ensuring ongoing safety for workers.

Electrochemical Sensors Explained

Electrochemical sensors are one of the most common types of detectors for hydrogen cyanide. They function by detecting chemical concentrations through an electrochemical reaction. These sensors are known for their accuracy in low concentration detection, along with the ability to provide rapid response times. When properly calibrated and maintained, electrochemical sensors can play a critical role in safeguarding industrial environments against HCN exposure.

Advanced Features and Variations

Modern hydrogen cyanide detectors are equipped with advanced features such as digital displays, audible alarms, and connectivity options for data logging and remote monitoring. Some models include GPS for location tagging, enhancing the ability to track data points in large industrial setups. Moreover, certain detectors offer multi-gas detection capabilities, allowing them to identify a range of hazardous gases, maximizing safety in various applications.

Choosing the Right Hydrogen Cyanide Detector

Evaluating Detection Technologies

When selecting a hydrogen cyanide detector, evaluating different detection technologies is fundamental. Factors to consider include detection sensitivity, response time, durability, and ease of use. Additionally, understanding the specifics of the working environment—such as temperature, humidity, and potential interferences—is crucial for determining the most suitable detection technology.

Factors to Consider: Environment & Application

The environment and intended application significantly influence the choice of hydrogen cyanide detectors. For dynamic and unpredictable environments, portable detectors might be preferable, whereas fixed detectors could be beneficial in consistent settings such as chemical plants. Additionally, factors like the presence of other chemicals, worker density, and potentially harmful interactions must be considered when making a selection.

Cost vs. Effectiveness Analysis

While it is tempting to opt for the least expensive option when purchasing detectors, a cost-effectiveness analysis is critical. High-quality hydrogen cyanide detectors may require a higher initial investment but can prove more economical in the long run through lower maintenance costs, superior durability, and enhanced safety reliability. Evaluating this balance can protect both personnel and resources effectively.

Best Practices for Using Hydrogen Cyanide Detectors

Installation Guidelines

Proper installation of hydrogen cyanide detectors is essential to ensure their effectiveness. Detectors should be placed in areas where HCN is most likely to accumulate, at breathing height for personnel, and away from obstructions that could hinder air circulation. Following manufacturer guidelines, along with consultation with safety engineers, is crucial during the installation process.

Regular Maintenance and Calibration

Maintenance and calibration of hydrogen cyanide detectors are vital to ensure accurate readings and reliability. Regular inspection schedules should be established to check sensor functionality, battery levels, and overall equipment condition. Calibration must be done according to the manufacturer’s specifications, typically on an annual basis but more frequently if used in volatile conditions.

Training Personnel for Effective Use

Training personnel to effectively use hydrogen cyanide detectors is another critical component in the safety chain. Employees should be educated on operational protocols, recognition of symptoms of HCN exposure, and immediate action plans for potential alarms. This knowledge not only enhances the safety apparatus but also creates a culture of safety within the workplace, empowering workers to respond promptly in emergencies.

Regulations and Compliance for Hydrogen Cyanide Monitoring

Understanding Regulatory Standards

Understanding the regulatory landscape surrounding hydrogen cyanide is imperative for compliance and safety in industrial settings. Organizations must adhere to established standards set by bodies such as the Occupational Safety and Health Administration (OSHA) and the National Institute for Occupational Safety and Health (NIOSH), which outline permissible exposure limits (PEL) and the necessary precautions for workplaces dealing with hazardous gases.

Documentation and Reporting Requirements

Documentation plays a fundamental role in the compliance framework for hydrogen cyanide monitoring. Employers are typically required to keep detailed records of monitoring results, maintenance schedules, and training activities. This information can serve as evidence for regulatory compliance during inspections and demonstrate a commitment to safety practices within the organization.

Future Trends in Gas Detection Safety

Innovation continues to drive advancements in gas detection technologies, and hydrogen cyanide detectors are no exception. Future trends may include integration with IoT technologies for remote monitoring and data analytics to predict unsafe conditions before they become critical. Furthermore, enhanced sensors that utilize artificial intelligence and machine learning capabilities for improved accuracy and predictive maintenance are on the horizon, promising a safer workplace environment.