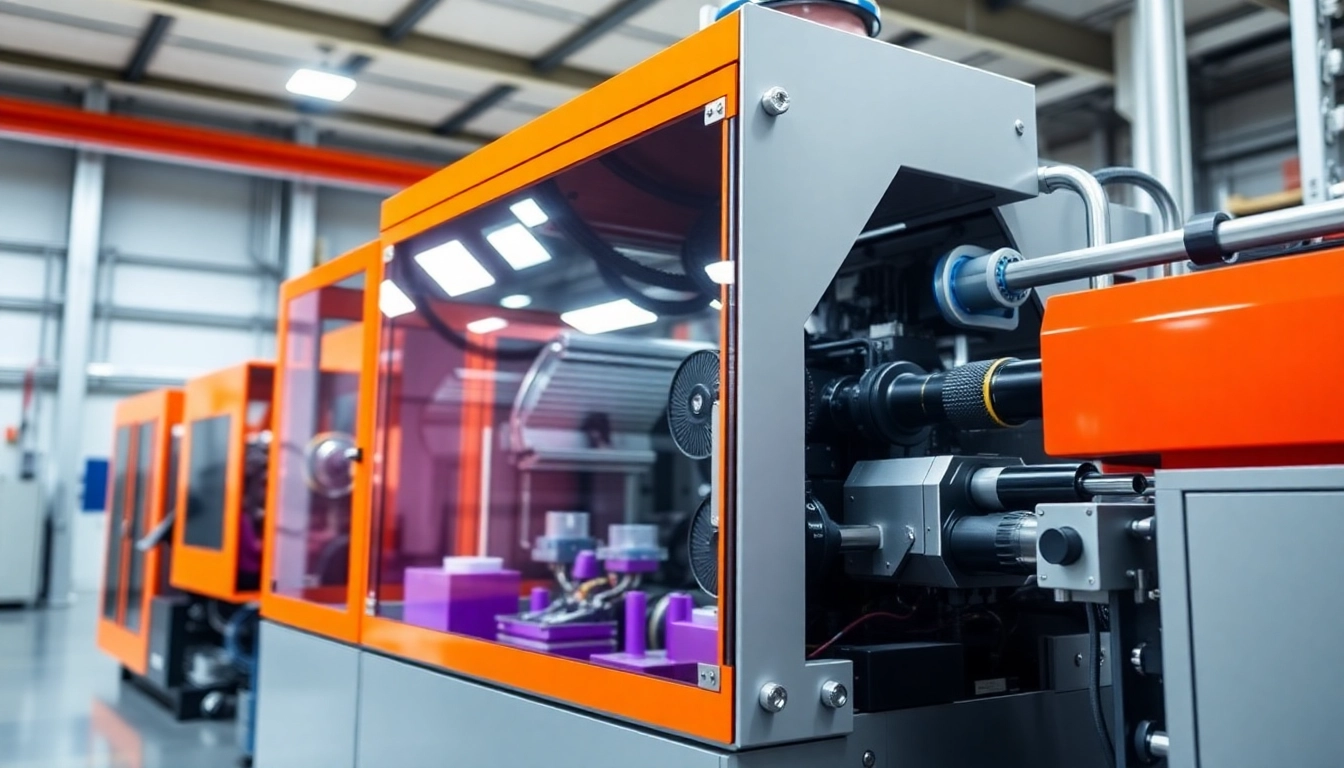

Understanding Blow Molding Technology

The industry of manufacturing plastic products has undergone significant transformations over the years, with blow molding emerging as one of the most preferred processes. The ability to create hollow containers, from simple bottles to complex shapes, has placed blow molding at the forefront of manufacturing. For businesses in the plastic product sector, partnering with a reliable Blow Molding Machine Manufacturer can enhance production efficiency and product quality, making knowledge of this technology critical.

The Process: What is Blow Molding?

Blow molding is a manufacturing process that involves inflating a heated plastic tube (or parison) into a mold to achieve a specific shape. This technique is comparable to glassblowing, as both processes involve air pressure to form the desired shape from a malleable medium. The blow molding process is typically divided into three main types: extrusion blow molding (EBM), injection blow molding (IBM), and stretch blow molding (SBM). Each type offers unique advantages suited for various applications.

Types of Blow Molding Techniques

Understanding the different types of blow molding techniques is essential for selecting the appropriate method for your production requirements:

- Extrusion Blow Molding (EBM): This technique involves extruding heated plastic into a parison and inflating it in a mold. It’s typically used for manufacturing containers, bottles, and large hollow parts.

- Injection Blow Molding (IBM): Combining injection molding and blow molding, IBM is ideal for creating precise and complex shapes. It uses preformed plastic to achieve high-quality finishes on smaller parts like medical devices and cosmetics bottles.

- Stretch Blow Molding (SBM): This method involves stretching the parison while being inflated, which enhances the strength and clarity of the plastic. It’s widely used for producing PET bottles, especially in beverage applications.

Applications of Blow Molding in Industries

Blow molding technology serves various industries, including:

- Consumer Goods: Packaging for beverages, household products, and personal care items.

- Automotive: Production of fuel tanks, air ducts, and other exterior components.

- Industrial: Manufacturing containers for chemicals, oils, and industrial machinery parts.

Key Features of Advanced Blow Molding Machines

When assessing blow molding machines, several key features determine their efficiency and effectiveness. A thorough understanding of these characteristics can help manufacturers choose the best equipment for their needs.

Efficiency and Speed in Manufacturing

Modern blow molding machines are designed for high efficiency and speed. Factors such as reduced cycle time, increased output rates, and improved energy consumption contribute to maximizing productivity. Manufacturers should consider machines that offer automation capabilities, such as robotic handling systems, to further enhance efficiency in workflow.

Eco-friendly Options in Blow Molding

Environmental concerns have prompted blow molding manufacturers to develop eco-friendly solutions. These include the use of recyclable materials, energy-efficient machines, and waste reduction techniques. For instance, the integration of sustainable materials like bioplastics is gaining traction, aligning production with eco-conscious consumer demands.

Customizations for Diverse Production Needs

Advanced blow molding machines come with customization features to cater to various production needs. Manufacturers can modify key parameters, such as mold design, cooling systems, and machine size, to produce unique products tailored to specific market demands. This level of customization is particularly crucial in industries that require specialized shapes and sizes.

Choosing the Right Blow Molding Machine Manufacturer

Selecting a reputable blow molding machine manufacturer is critical to ensuring the quality and reliability of your production line. Here are essential considerations when evaluating potential partners.

Evaluating Manufacturer Experience and Expertise

Experience in the industry often correlates with a manufacturer’s understanding of market needs and technological advancements. Companies with a diverse portfolio and years of operation typically possess the knowledge to handle varying manufacturing requirements efficiently.

Technological Innovations to Look For

It is essential to understand the level of technology being used by a manufacturer. Look for companies that invest in research and development to stay at the forefront of industry advancements. Features like automation, IoT integration, and data analytics can significantly enhance production capabilities.

Customer Support and Service Assessments

Strong customer support can be a game-changer in manufacturing. Assess how manufacturers provide training, maintenance, and technical support. A responsive customer service team can assist organizations in resolving issues quickly and minimizing downtime in production.

Cost Considerations and Investment Returns

Investing in blow molding machinery represents a significant financial commitment. Understanding cost considerations and potential returns on investment (ROI) can help guide the purchasing decision.

Initial Investment vs. Long-Term Savings

While the initial cost of advanced blow molding machines may be higher, the long-term savings often justify the expenditure. Consider factors such as lower energy consumption, faster production times, and reduced labor costs when calculating potential savings.

Comparative Analysis of Market Pricing

Conducting a comparative analysis of market pricing ensures that businesses obtain fair value for their investment. Gather quotes from several manufacturers, keeping in mind that the lowest price does not always equate to the best quality. Evaluate each option based on machine specifications, after-sales service, and warranty terms.

Financing Options for Manufacturers

Many manufacturers offer financing schemes to aid businesses in acquiring new equipment. Exploring options such as leasing or installment payments allows manufacturers to manage cash flow effectively while acquiring the necessary machinery.

Future Trends in Blow Molding Technology

The future of blow molding technology is poised for exciting developments. Understanding emerging trends can help manufacturers stay competitive and innovative.

The Impact of Automation and AI

Automation and artificial intelligence play pivotal roles in modern manufacturing. The integration of these technologies into blow molding processes can drastically increase production efficiency, reduce human error, and facilitate data collection for informed decision-making.

Sustainable Practices in Manufacturing

Sustainability is becoming increasingly critical in manufacturing, and blow molding is no exception. Efforts to ensure sustainable practices, from sourcing biodegradable materials to implementing eco-friendly processes, are essential for compliance with regulations and meeting consumer expectations.

Emerging Markets and Applications

Emerging markets are expanding opportunities for blow molding technology. As countries develop their manufacturing capabilities, there are new applications for blow-molded products across various sectors, including healthcare, packaging, and automotive. Manufacturers must be adaptive to these changes and explore innovative product designs to capture these new markets.