Understanding Clamp on Hose Basics

Hoses play a pivotal role in various industrial and residential applications, delivering fluids efficiently from one point to another. Integral to their functionality are clamp on hose fittings that provide essential security and reliability in fluid transfer. This article delves deep into the intricacies of clamp on hoses, offering comprehensive insights that can enhance understanding and application.

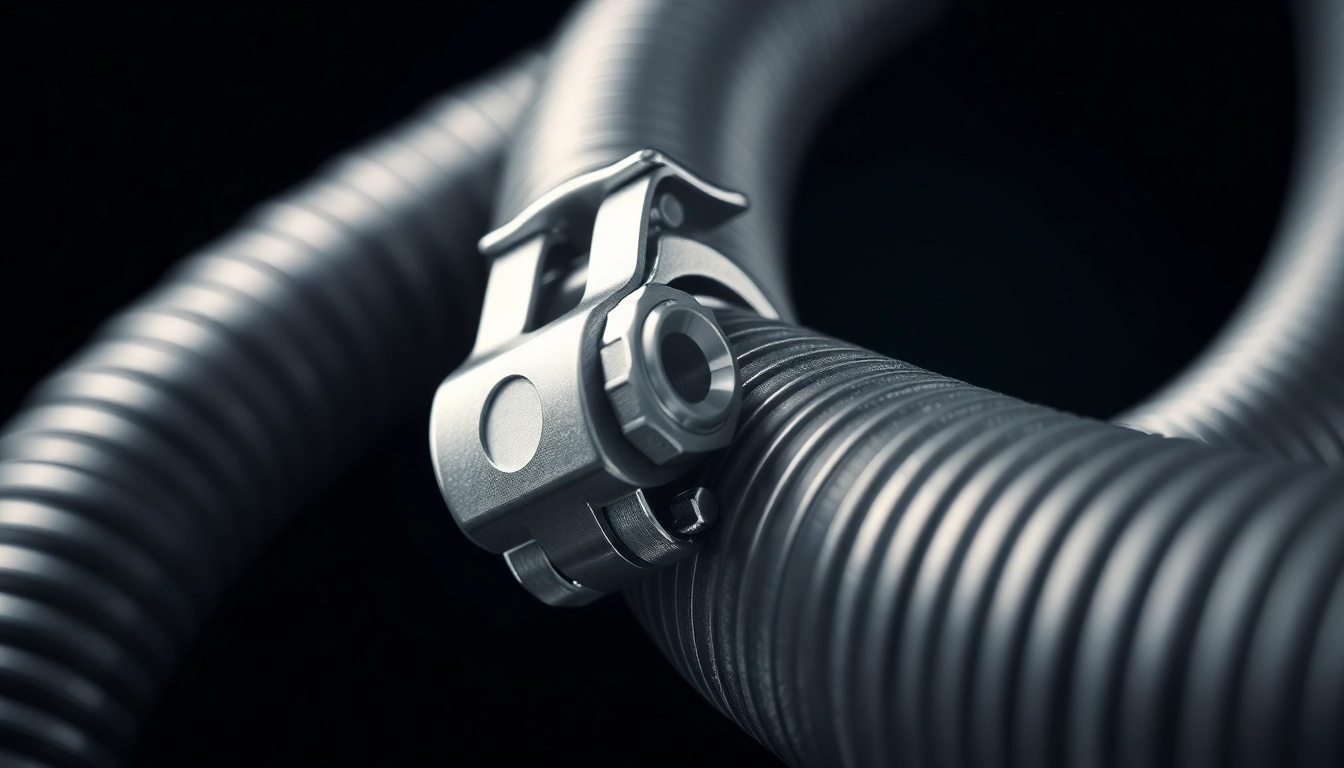

What is a Clamp on Hose?

A clamp on hose is a type of flexible tubular structure designed to channel gases or liquids. What sets it apart is its ability to be securely fastened using a clamp—an essential component that ensures a leak-proof seal at the connection points. This fastening capability make these hoses indispensable in various settings, from automotive mechanics to plumbing and industrial processes.

Key Features and Benefits of Clamp on Hose Options

- Durability: Most clamp on hoses are made from robust materials like rubber or PVC, ensuring they withstand high pressures and extreme conditions.

- Ease of Installation: These hoses often come with pre-attached clamps or are designed for compatible clamping systems, facilitating quick and easy setup.

- Versatility: They are suitable for various applications, from air and liquid transfer to vacuum systems.

- Adjustability: Many clamp on hoses are designed to be trimmed, allowing for customized lengths tailored to specific applications.

- Leak Prevention: The secure connection provided by clamps minimizes the risk of leaks significantly compared to unfastened hoses.

Types of Clamp on Hoses and Their Uses

Clamp on hoses come in various types, each designed for specific applications:

- Silicone Hoses: Commonly used in automotive applications due to their resistance to high temperatures and flexibility.

- Rubber Hoses: Ideal for lower pressure applications and often used in domestic plumbing and irrigation systems.

- PVC Hoses: A lightweight option commonly used for water transfer, gardening, and low-pressure air delivery.

- Stainless Steel Hoses: Typically used in food processing and chemical industries due to their resistance to corrosion.

Choosing the Right Clamp on Hose

Factors to Consider When Selecting a Clamp on Hose

Selecting the right clamp on hose requires careful consideration of various factors to ensure optimal performance:

- Pressure Rating: Ensure the hose can handle the maximum operating pressure expected in its application.

- Temperature Resistance: Choose a hose that can withstand the temperatures it will encounter—high temperatures may necessitate silicone materials.

- Material Compatibility: Ensure the hose material is compatible with the substance it will be transporting to avoid degradation or contamination.

- Application Type: Different applications may require unique features, such as flexibility, anti-kinking properties, or abrasion resistance.

Common Applications for Clamp on Hoses

Clamp on hoses are widely utilized across numerous sectors:

- Automotive: For coolant transfer, air intake systems, and fuel lines.

- Industrial: In manufacturing and processing plants for fluid handling and transfers.

- Agricultural: Watering systems and irrigation setups.

- Filtration Systems: Connecting filters to piping systems.

Top Brands and Their Offerings

Several reputable brands dominate the clamp on hose market:

- Gates: Known for high-performance products, especially in automotive applications.

- Hose Master: Specializes in metal hoses and flexible connectors with a focus on quality and durability.

- Goodyear: Offers a range of industrial hoses, including rubber and PVC hoses.

- Silicone Engineering: Renowned for quality silicone hoses ideal for automotive and high-temperature applications.

Installation Tips for Clamp on Hoses

Preparing for Installation: Tools and Materials

Before embarking on the installation of a clamp on hose, gather the necessary tools and materials:

- Hose and Clamps: Ensure they are the correct sizes and materials for your intended application.

- Hose Cutting Tool: A sharp knife or specialized hose cutter for sizing the hose appropriately.

- Hose Clamps: Choose quality clamps that fit the hose diameter snugly.

- Screwdriver or Wrench: Depending on the type of clamps used, you may need these tools for tightening the clamps.

- Lubricant: Use a silicone-based lubricant to ease the hose onto barbs and fittings if necessary.

Step-by-step Guide to Installing Clamp on Hoses

- Measure and Cut: Measure the required length needed for your application and cut the hose accurately.

- Prepare Connections: Ensure that the connection points are clean and free from debris.

- Attach the Hose: Slide the hose onto the fitting or barb, pushing firmly until it is secure.

- Position the Clamp: Place the clamp over the hose at the connection point, ensuring it covers the barbed area entirely.

- Tighten the Clamp: Using your screwdriver or wrench, tighten the clamp evenly to create a secure fit without over-tightening.

- Test for Leaks: Once installed, run a test to check for leaks and ensure everything is functioning as it should.

Common Mistakes to Avoid When Installing

To ensure a successful installation, be mindful of these common pitfalls:

- Using the Wrong Clamp Size: Ensure that the clamp size matches the hose diameter for a snug fit.

- Over-tightening: Excessive tightening can damage the hose and fittings, leading to leaks.

- Ignoring Compatibility: Ensure the hose is compatible with the application to avoid chemical reactions.

- Neglecting Regular Checks: Regularly check connections to avoid leaks and wear issues.

Maintenance and Care for Clamp on Hoses

Regular Maintenance Tips

Maintenance is critical for the longevity of clamp on hoses. Consider the following:

- Routine Inspections: Regularly check hoses and clamps for signs of wear or deterioration.

- Cleanliness: Keep connection points clean to prevent debris buildup, which can lead to leaks.

- Monitor for Leaks: Regularly test for leaks, especially in high-pressure applications.

- Proper Storage: Store hoses in a cool, dry place away from direct sunlight to prevent degradation.

Identifying Signs of Wear and Tear

Knowing the signs that indicate a need for replacement can save time and money:

- Visible Cracks or Cuts: Any cracks or severe abrasions on the hose’s surface should be inspected closely.

- Soft Spots or Swelling: These can indicate internal damage; replace immediately if detected.

- Frequent Leaks: If you notice recurring leaks, it may indicate that the hose has reached the end of its service life.

Best Practices for Extending Life of Your Clamp on Hose

To maximize the lifespan of your clamp on hoses, implement these best practices:

- Follow Manufacturer Guidelines: Always adhere to the recommended specifications for installation and use.

- Avoid Extreme Conditions: Keep hose applications within the defined temperature and pressure limits.

- Use Protective Covers: Where possible, use protective sleeves to shield hoses from external abrasions.

Comparative Analysis of Clamp on Hoses

Clamp on Hose vs. Traditional Hoses: A Comparison

Understanding the differences between clamp on hoses and traditional hoses can guide better purchasing decisions:

- Connection Types: Clamp on hoses typically offer secure, adjustable connections while traditional hoses may rely solely on friction.

- Sealing Capabilities: Clamp systems provide stronger seals, reducing the likelihood of leaks.

- Flexibility: While both types offer flexibility, clamp on hoses tend to allow more customization in terms of fittings.

Price Breakdown: Budget-Friendly Options vs. Premium Products

When considering clamp on hoses, pricing can vary significantly based on material, brand, and application suitability:

- Budget-Friendly Options: Generally range from $5 to $20, ideal for light-duty applications.

- Premium Products: High-quality hoses made from specialized materials may range from $20 to $100+ but offer improved durability and performance.

Customer Reviews and Recommendations for Clamp on Hoses

Feedback from actual users can provide invaluable insights when selecting clamp on hoses:

- High Durability Feedback: Many users praise the long-lasting nature of silicone hoses, particularly in automotive applications.

- Positive Experiences with Installation: Users highlight how easy most clamp on hoses are to install, often requiring minimal tools.

- Comparative Performance: Users frequently compare products, noting that higher-priced hoses often yield superior results in heavy-duty applications.