Understanding Oxy Gas Welding Kits

What is an Oxy Gas Welding Kit?

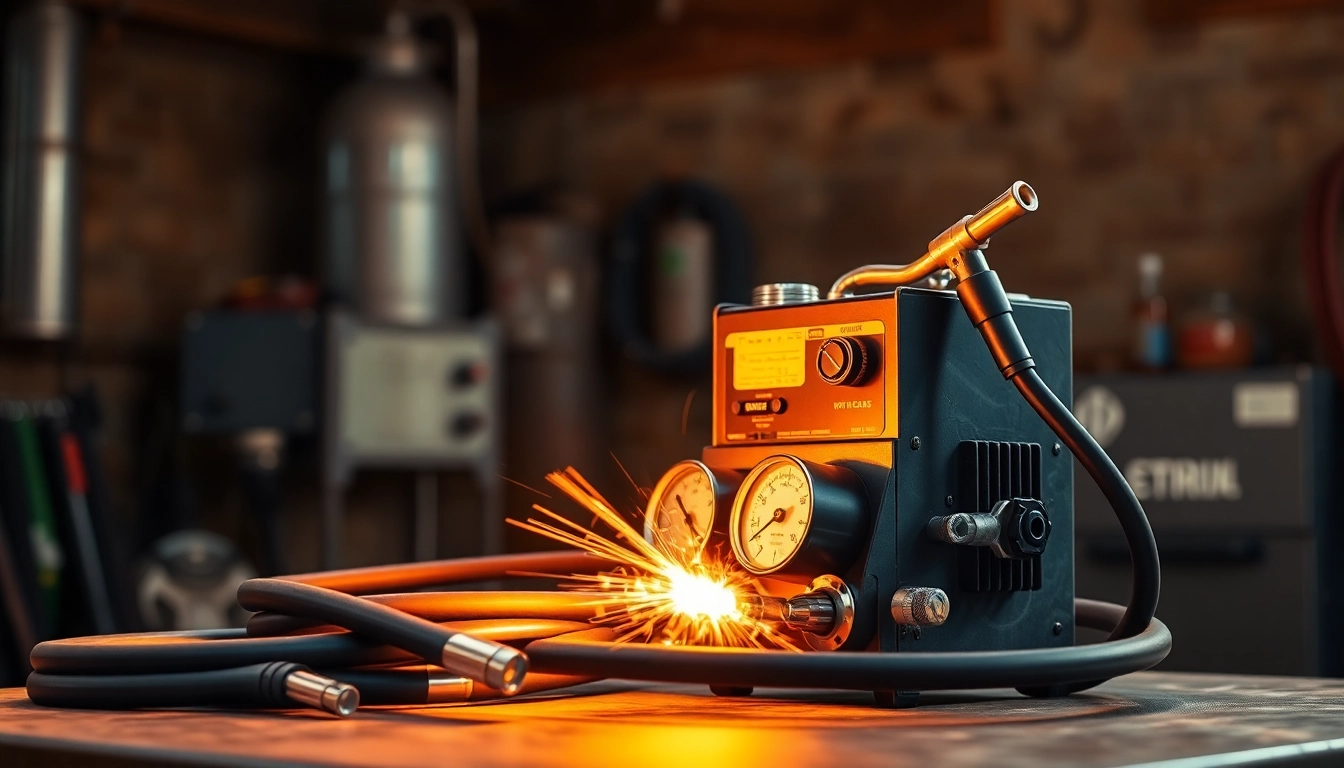

An oxy gas welding kit is an essential tool set used primarily for welding, cutting, and heating applications. The kit operates on the principle of oxy-fuel welding, which combines oxygen with a fuel gas, typically acetylene, to produce a high-temperature flame. This flame is capable of melting steel and other metals, allowing them to be joined together. Oxy gas welding is widely used in various industries, including construction, automotive repair, and metal fabrication due to its versatility and effectiveness.

Key Components of an Oxy Gas Welding Kit

A comprehensive oxy gas welding kit typically includes several key components:

- Welding Torch: The primary tool used to mix oxygen with acetylene and ignite the flame.

- Gas Regulators: Devices that control the pressure and flow of oxygen and acetylene.

- Gas Cylinders: Tanks that store the oxygen and acetylene gas under pressure.

- Hoses: Flexible tubes that transport gas from the cylinders to the torch.

- Welding Goggles and Gloves: Essential personal protective equipment (PPE) to ensure safety during operation.

- Welding Rods: Filler materials used to enhance the strength and durability of the weld.

- Cutting Tips: Specialized nozzles for cutting through metal.

How Oxy Gas Welding Works

The welding process begins by igniting the mixture of oxygen and acetylene in the welding torch, which produces a flame with temperatures reaching up to 3,500 degrees Celsius (6,332 degrees Fahrenheit). This extremely hot flame allows for the melting of metals. The welder typically manipulates the torch to control the intensity and location of the flame, thereby influencing the quality of the weld. The precise application of heat is crucial for achieving strong and reliable welds, making the welder’s skill and experience an indispensable asset.

Types of Oxy Gas Welding Kits

Commercial vs. Hobbyist Oxy Gas Welding Kits

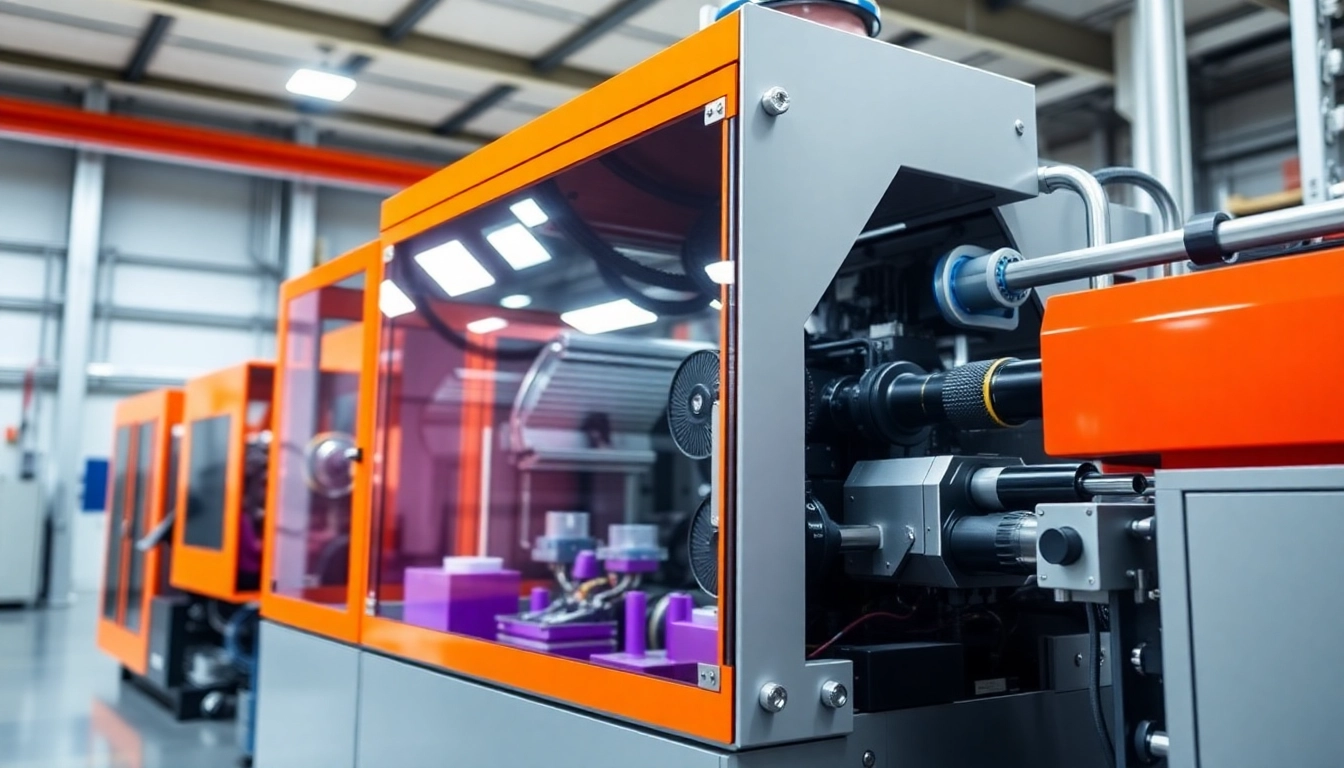

Oxy gas welding kits are available in various configurations designed to meet the specific needs of different users. Commercial kits, often more robust and expensive, are built for heavy-duty tasks. These kits feature higher-grade materials and additional components, such as advanced regulators and larger gas tanks, making them suitable for professional applications where consistent performance is mandatory. In contrast, hobbyist kits are typically less expensive, designed for light-duty tasks such as craft projects or repairs, and are often more portable.

Portable vs. Stationary Kits

Portability is another aspect to consider when choosing an oxy gas welding kit. Portable kits are lighter and more compact, making them ideal for mobile work applications, such as field repairs or jobs that require travel. Stationary kits, on the other hand, are larger and may contain more features, being best suited for fixed locations, like workshops or manufacturing plants. The choice between portable and stationary will depend largely on the nature of the intended applications and the working environment.

Comparing Oxy-Acetylene and Propane Kits

While oxy-acetylene welding is one of the most common methods, propane welding kits offer an alternative. Propane burns cooler than acetylene and is often used for tasks that do not require the high temperatures produced by acetylene, such as brazing and light welding. The main benefits of propane kits include cost-effectiveness and easier storage, making them appealing to smaller operations or hobbyists. However, for heavier industrial applications requiring deep penetration welding, oxy-acetylene remains the preferred choice.

Choosing the Right Oxy Gas Welding Kit

Assessing Your Welding Needs

Before selecting an oxy gas welding kit, assess your specific needs. Consider the types of materials you will be working with, the thickness of the metals, and the frequency of use. For instance, if you are only planning occasional repairs, a lighter, hobbyist kit may suffice. Conversely, if you are welding thicker materials regularly, a commercial-grade oxy gas welding kit would be a more suitable investment.

Key Features to Look For

When shopping for an oxy gas welding kit, several features should be prioritized:

- Regulator Quality: Ensure that the gas regulators are reliable and accurate as they influence the precision of the weld.

- Welding Torch Design: Look for ergonomic and adjustable designs that allow easy flame control.

- Safety Features: Check for safety mechanisms such as flashback arrestors and check valves to prevent gas backflow.

- Accessories: Consider kits that include necessary accessories, such as different nozzle sizes for varying applications.

Price Ranges and Budgeting for Your Kit

The price of oxy gas welding kits can vary significantly based on quality and included features. On the lower end, hobbyist kits can start around $100, appealing to occasional users. Mid-range kits suitable for light industrial use can cost between $300 and $600, while commercial-grade kits can exceed $1,000, depending on the complexity and additional tools included. It’s vital to find a balance between your budget and your specific welding needs, prioritizing quality and safety features within your price range.

Maintenance and Safety Tips

Proper Care for Your Oxy Gas Welding Kit

Regular maintenance of your oxy gas welding kit is crucial for safety and efficiency. Here are some essential maintenance tips:

- Check for Leaks: Regularly examine hoses and connections for leaks by applying soap water and looking for bubbles.

- Clean the Torch: Ensure that the torch tip is free from obstructions and buildup for optimal performance.

- Store Properly: Store gas cylinders upright and secure, away from heat sources to prevent any accidents.

Essential Safety Practices When Welding

Safety practices are paramount when working with oxy gas welding kits. Always wear appropriate PPE, including goggles, gloves, and flame-resistant clothing. Ensure adequate ventilation in your workspace to avoid the accumulation of hazardous gases. Familiarize yourself with the operation manual of your kit and follow all manufacturer guidelines. Furthermore, having a fire extinguisher within reach is critical, as welding sparks can ignite flammable materials.

Common Issues and Troubleshooting Tips

Welding can often present challenges, but being prepared with troubleshooting tips can save time and effort. Common issues include:

- Flame Problems: If the flame is too small or unstable, check the gas pressure and ensure that the regulators are set correctly. Adjust the ratio of oxygen to acetylene for optimal results.

- Brazing Difficulties: If the metal does not bond well, consider cleaning the surfaces thoroughly and ensure proper heating before introducing the filler material.

- Backfire Issues: Backfires can occur due to improper adjustment; ensure that hoses are secured, and use flashback arrestors to prevent occurrences.

Conclusion and Recommendations

Top Oxy Gas Welding Kits on the Market

When it comes to selecting an oxy gas welding kit, several top brands consistently receive high marks for performance and reliability. Some recommended brands include:

- Victor: Known for its high-quality torches and robust kits, Victor provides excellent options for serious welders.

- Harris: Offers a variety of kits suitable for both professional and hobbyist use, often praised for durability.

- Lincoln Electric: Renowned for innovative designs and advanced technology, particularly in their heavier duty kits.

How to Make the Most of Your Oxy Gas Welding Kit

To maximize your welding capabilities, regularly practice and refine your skills. Enroll in welding classes, join local workshops, or follow online tutorials to enhance your techniques. Understanding different welding techniques such as cutting, braze welding, and soldering will also expand your skill set. Moreover, staying updated with the latest industry trends and technology improvements will ensure that you utilize your oxy gas welding kit to its fullest potential.

Resources for Further Learning

There are plenty of resources available for those looking to expand their knowledge of oxy gas welding:

- Xometry’s guide to types of gas welding offers valuable insights.

- Local community colleges often provide welding courses, which can be a valuable way to gain real-world experience.

- Online forums and welding communities can provide support, tips, and advice based on real-world experiences from other welders.