Understanding HPMC Manufacturer: An Overview

Hydroxypropyl methylcellulose (HPMC) is a versatile cellulose ether that plays a crucial role in various industries. As a significant ingredient in pharmaceutical, cosmetic, construction, and food applications, it is produced by HPMC manufacturers worldwide. The significance of choosing a reputable HPMC manufacturer cannot be understated, as quality and consistency in production directly impact the effectiveness of the end products. This article delves into the properties, applications, and future trends of HPMC, providing valuable insights into why collaboration with a reliable manufacturer is vital.

What is HPMC and Its Key Properties?

HPMC, or hydroxypropyl methylcellulose, is a semi-synthetic polymer derived from cellulose, a naturally occurring polymer. It is widely admired for its exceptional properties, including:

- Solubility: HPMC is soluble in water and forms a gel-like consistency, making it highly suitable as a thickener or binder in formulations.

- Viscosity: Its ability to enhance viscosity allows for improved texture and stability in products.

- Film-forming ability: HPMC can create a film on surfaces, providing moisture resistance and protection.

- Biocompatibility: As a safe and non-toxic compound, HPMC is widely used in health and personal care products without adverse effects.

- Temperature Stability: It remains stable across a broad temperature range, ensuring effectiveness in various applications.

The Role of HPMC in Various Industries

The versatility of HPMC allows it to play important roles in numerous sectors:

- Pharmaceuticals: Used as a binding agent in tablets and as a suspending agent in liquid formulations.

- Cosmetics: Applied as a thickener and stabilizer in creams, lotions, and gels.

- Construction: Enhances the performance of mortars and plasters.

- Food Industry: Acts as a thickening and stabilizing agent in food products.

Why Choose a Reliable HPMC Manufacturer?

Partnering with a trusted HPMC manufacturer ensures that the products adhere to industry standards, providing numerous benefits:

- Quality Assurance: Reliable manufacturers implement strict quality control measures to guarantee product consistency.

- Regulatory Compliance: Established manufacturers comply with regulations for safe use in health-related applications.

- Technical Support: A good manufacturer can offer expert guidance on the optimal use of HPMC in specific applications.

- Innovation and Development: Leading HPMC manufacturers continually invest in research and development to improve product performance and address emerging market needs.

Applications of HPMC in Health and Personal Care

Benefits of HPMC in Pharmaceutical Formulations

HPMC is integral in the pharmaceutical industry due to its multifunctionality. It serves as a binding agent, improving the mechanical properties of tablets and ensuring uniform drug distribution. Furthermore, its gel-forming capabilities facilitate controlled drug release, which is essential for enhancing therapeutic efficacy.

HPMC in Cosmetics: Enhancing Product Performance

In cosmetics, HPMC contributes to product stability and texture. It enhances the feel of creams and lotions while preventing separation of ingredients, thereby extending shelf life. Additionally, its film-forming properties provide enhanced moisture retention, making it a popular choice in skincare formulations.

Regulatory Standards and Quality Assurance

Health and safety regulations govern the use of HPMC in health-related products. Manufacturers must adhere to guidelines set forth by regulatory bodies, ensuring that HPMC is safe for human consumption and topical application. Quality assurance processes, including batch testing and validation protocols, are critical to maintaining these standards.

HPMC in Construction: A Versatile Additive

Improving Mortar and Plaster with HPMC

In the construction industry, HPMC is added to mortars and plasters to enhance workability, adhesion, and water retention. Its ability to extend the open time of mixtures allows for improved application and finishing. As a result, construction professionals can achieve better durability and performance in building materials.

HPMC’s Role in Eco-Friendly Construction Solutions

As sustainability becomes ever more essential in construction, HPMC plays a key role in eco-friendly practices. By improving the performance of lower-impact materials, HPMC contributes to reducing the environmental footprint of construction processes. Additionally, it enables the formulation of green building materials, such as low-VOC products that meet regulatory criteria for indoor air quality.

Cost-Benefit Analysis of Using HPMC

While the initial investment in HPMC may be higher compared to traditional additives, the long-term benefits often outweigh costs. Reduced need for repairs, enhanced product lifespan, and improved user satisfaction lead to overall cost savings. A thorough cost-benefit analysis can reveal significant financial advantages, reinforcing the value of HPMC in construction applications.

Production Techniques of HPMC: Best Practices

Raw Materials and Sourcing Strategies

The quality of HPMC starts with high-grade raw materials. Manufacturers must identify reliable sources for cellulose derivatives, ensuring they meet the necessary purity standards for effective production. Investments in sustainable and ethical sourcing not only enhance the product quality but also contribute to overall environmental responsibility.

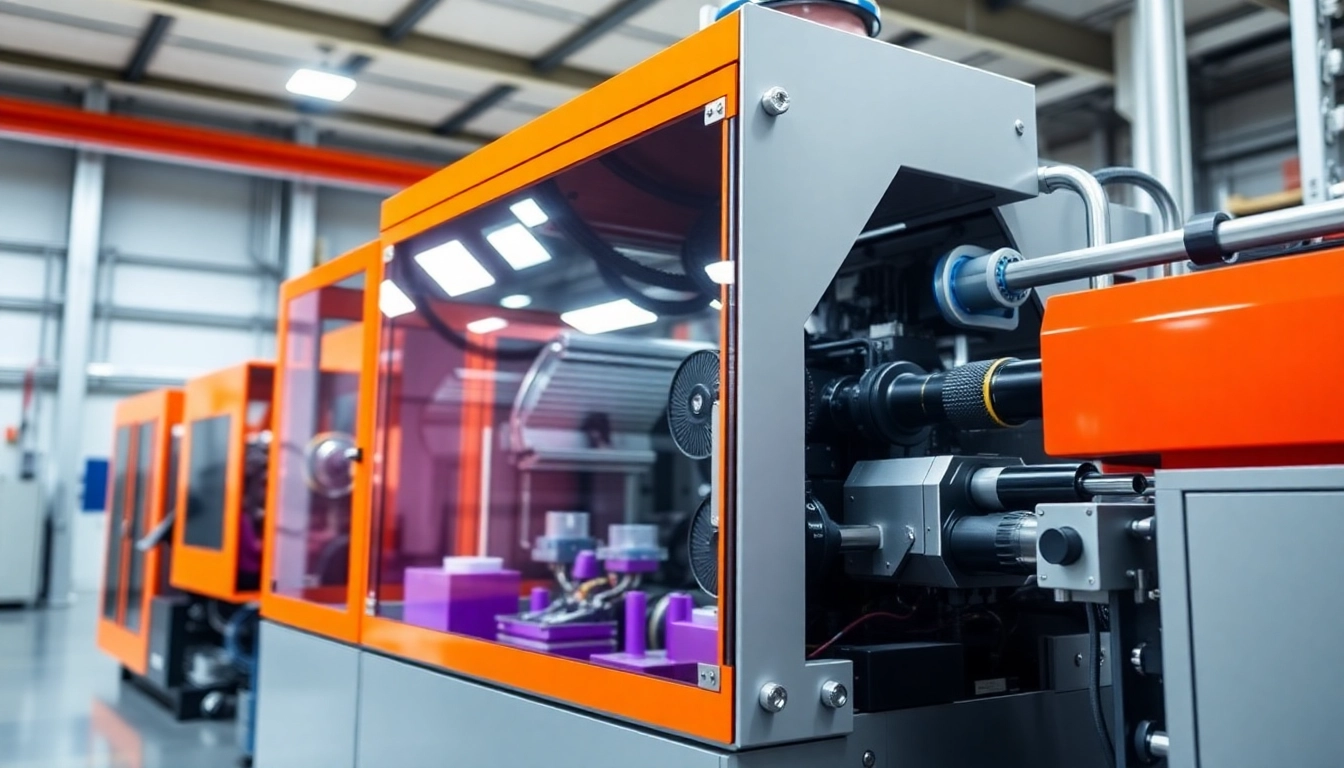

Advanced Manufacturing Processes and Technologies

State-of-the-art manufacturing processes are critical for producing high-quality HPMC. Advanced technologies, such as continuous processing and precision mixing, can significantly improve efficiency and batch consistency. Implementing automation in production can further enhance quality control, ensuring that products meet stringent specifications.

Quality Control Measures in HPMC Production

Quality control in HPMC production consists of a multi-faceted approach that includes in-process monitoring, end-product testing, and compliance audits. Rigorous quality control not only prevents defects but also bolsters the manufacturer’s reputation. Regular audits and reviews ensure continuous adherence to both internal standards and regulatory requirements.

Future Trends and Innovations in HPMC Manufacturing

Emerging Applications of HPMC in New Markets

As industries evolve, so too does the application of HPMC. Emerging markets in biotechnology and environmentally friendly products highlight opportunities for HPMC’s integration. The adaptability of this polymer makes it an attractive option for innovative product development across multiple domains.

Adapting to Sustainability Trends in Manufacturing

Sustainability in HPMC manufacturing focuses on reducing waste, energy consumption, and emissions. Manufacturers are increasingly adopting green chemistry principles, modifying processes to minimize environmental impact. The integration of biodegradable alternatives into formulations exemplifies a commitment to sustainable practices.

Innovation and Research Directions for HPMC Manufacturers

Ongoing research into HPMC’s properties can lead to the discovery of novel applications, expanding its suitability across a diverse range of industries. Collaborations with research institutions can foster innovation, promoting the development of modified HPMC with enhanced functionalities that cater to specific market needs.